Motivation and research gaps

Earth Overshoot Day, i.e. the day on which humanity's demand for natural resources exceeds the Earth's ability to regenerate, has already shifted forward from December 30 to July 28 in 2022 since it was first calculated in 1970. This rapid increase in global resource consumption means that 1.75 Earths would have been needed in 2022 to cover humanity's global resource consumption. [Glo-22]

The circular economy offers a solution to this problem and is defined as an industrial model that decouples production output and resource consumption and is therefore inherently restorative and regenerative [EMF-13]. A broad range of research will therefore be required in the upcoming years in order to establish circular economy patterns and thus achieve the EU's climate neutrality targets by 2050 and Germany's by 2045 [BDI-21]. In addition to the creation of the necessary legal and regulatory conditions and the development of suitable business models for the circular economy, research and the development of technologies are particularly necessary to enable the transformation from a linear economy to a climate-neutral circular economy on an industrial scale [BDI-21].

The Collaborative Research Centre 1574 "Circular Factory for the Perpetual Product" addresses this need for research and innovation and aims to enable a breakthrough in circular production on an industrial scale.

Literature references:

| [Glo-22] | Global Footprint Network (2022): Past Earth Overshoot Days. Available online at https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an. |

| [EMF-13] | MacArthur, E. (2013): Towards the circular economy, economic and business rationale for an accelerated transition. Available online at https://ellenmacarthurfoundation.org/towards-the-circular-economy-vol-1-an-economic-and- business-rationale-for-an. As at: 23.12.2020. |

| [BDI-21] | Bundesverband der Deutschen Industrie e.V. (2021): Klimapfade 2.0 - Wie wir unser Industrieland klimaneutral gestalten. |

Vision of the Collaborative Research Center

The vision of the Collaborative Research Centre is the integration of linear and circular production processes through a changeable and autonomous production system in order to realize the maximum retention of added value through the vision of the perpetual product as well as the integrated design of product (generations) and production systems in the sense of product-production co-design.

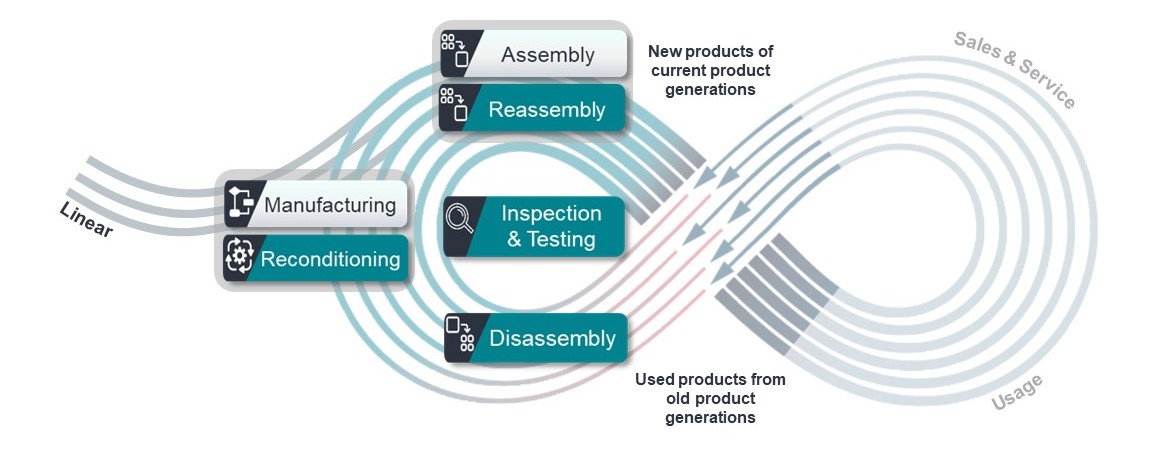

The products created in the circular factory should be qualified for the primary market by having a performance equivalent to purely linearly produced products while also being able to integrate innovative functions through technological updates. The aim is to minimize the need for new, purely linearly produced subsystems and components to be added or manufactured in the circular factory in order to competitively meet current market requirements. The transfer of a used product into newer product generations is based on the integrated design of product (generations) and production systems (product-production co-design). This is achieved by developing and integrating a methodical approach for product development, a design for circular factory for products that are tailored to circular processes. In order to make the vision of the perpetual product possible, it is necessary to combine circular production processes with existing linear production processes in an integrated production system (see figure).

Figure: Integrated production system for linear and circular production, green: focused process steps of circular production, white: focused process steps of linear production, based on [UN-15].

This integrated production system is capable of linear production of new products without reconditioning as well as the circular processes, using the same production resources to enable a highly efficient production system. This enables high-performance, high-efficiency mass production, as known from linear production. For the first time, new products with an individual refurbishment component can be produced on an industrial scale and thus with low unit costs (economies of scale) and sold economically on the market. Circular production processes can thus be established at the high-wage location in large-scale production and the value creation can be kept.

Literature references:

| [UN-15] | United Nations (2015): Sustainable Development Goals - Department of Economic and Social Affairs (UNDESA). |

| [LAN-23] | Lanza, G., Klenk, F., Martin, M., Brützel, O., & Hörsting, R. (2023). Sonderforschungsbereich 1574: Kreislauffabrik für das ewige innovative Produkt: Integrierte lineare und zirkuläre Produktion mittels hochvernetztem Produkt-Produktions-CoDesign. Zeitschrift für wirtschaftlichen Fabrikbetrieb, 118(12), 820-825 |

Subprojects

Research into such integrated value creation in a changeable, autonomous production system is accompanied by major challenges and requires comprehensive scientific consideration. The challenges of the circular factory with regard to this vision lie in particular in the uncertainty of used products due to individual and uncertain product states. The solution approach within the framework of the CRC project is therefore based on a high degree of flexibility, adaptability and autonomy of all production resources on the store floor, which adapt independently to constantly changing framework conditions and challenges. This results in the project area C: Integrated value creation planned in the CRC project (see figure).

Enabling learning production resources in the circular factory requires the detection and interpretation of uncertain objects and processes. The focus here is on the multi-sensory perception of products and people. People therefore play a central role at all times, as they represent a source of knowledge with regard to constantly new products or product generations and variants, as well as for changing framework conditions that arise due to external complexity. The solution approach within the framework of the CRC project thus pursues the multi-sensory recording and modeling of the unique product instance as well as the human process execution. This results in the project area B planned in the CRC project : Multi-sensory perception (see figure).

Rigid a priori planning and control of the closed-loop factory are not suitable due to the prevailing uncertainties. Instead, robust and at the same time dynamic order planning and dynamic scheduling are required to ensure that the circular factory can react quickly. As part of the Collaborative Research Center, the overarching design and control of the circular factory as an overall system is to be researched, resulting in the planned project area A: Product-Production-CoDesign (see figure).

Figure: Structure of the Collaborative Research Center 1574 Circular Factory for the Perpetual Product.

The following sub-projects are assigned to the project areas:

Project Area A

Subproject A01: Integrated Planning and Control of the Circular Factory

Principal Investigators: Prof. Dr.-Ing. G. Lanza; Pof. Dr.-Ing. N. Stricker

Subproject A02: Formal Representation of Adaptive Production Systems

Principal Investigators: Dr.-Ing. J. Pfrommer

Principal Investigators: Prof. Dr. rer. nat. S. Staab

Subproject A04: Integrated Description, Planning and Modeling of the Perpetual Product

Principal Investigators: Prof. Dr.-Ing. Dr. h. c. A. Albers; Prof. Dr.-Ing. T. Düser

Subproject A05: Functional Model of the Perpetual Product

Principal Investigators: Prof. Dr.-Ing. S. Matthiesen; Dr.-Ing. P. Grauberger

Subproject A06: Modeling of System Reliability

Principal Investigators: Prof. Dr.-Ing. S. Matthiesen

Project Area B

Subproject B01: Autonomous Measurement Strategies

Principal Investigators: Prof. Dr.-Ing. G. Lanza

Subproject B02: Detection of Material Influences

Principal Investigators: Dr.-Ing. S. Dietrich; Prof. Dr.-Ing. habil. V. Schulze

Subproject B03: Information Representation and Management of Product Instances

Principal Investigators: Prof. Dr.-Ing. habil. J. Beyerer; Prof. Dr.-Ing. M. Heizmann

Subproject B04: Recording the Human Being

Principal Investigators: Dr.-Ing. A. Roitberg; Prof. Dr.-Ing. habil. R. Stiefelhagen

Subproject B05: Learning from Human Eye and Gaze Behavior

Principal Investigators: Prof. Dr.-Ing. Dipl.-Psych. B. Deml

Project Area C

Subproject C01: Transformer Cell

Principal Investigators: Prof. Dr.-Ing. Fleischer

Principal Investigators: Prof. Dr.-Ing. F. Zanger; Prof. Dr.-Ing. habil. V. Schulze

Subproject C03: Autonomous Intralogistics in the Circular Factory

Principal Investigators: Prof. Dr.-Ing. K. Furmans

Subproject C04: Learning Task Models for Manipulation Tasks in the Closed-loop Factory

Principal Investigators: Prof. Dr.-Ing. T. Asfour

Subproject C05: Data- and Simulation-driven Transfer to the Transformer Cell

Principal Investigators: Prof. Dr.-Ing. G. Neumann

Principal Investigators: Prof. Dr. Rania Rayyes

Supporting subprojects

INF: Data Infrastructure for the Circular Factory

Principal Investigators: Prof. Dr. rer. nat. S. Staab; Dr.-Ing. M. Selzer; Prof. Dr.-Ing. G. Lanza

Principal Investigators: Prof. Dr.-Ing. Fleischer

Z: Central Administration Project

Principal Investigators: Prof. Dr.-Ing. G. Lanza

Literature references:

| [LAN-23] | Lanza, G., Klenk, F., Martin, M., Brützel, O., & Hörsting, R. (2023). Sonderforschungsbereich 1574: Kreislauffabrik für das ewige innovative Produkt: Integrierte lineare und zirkuläre Produktion mittels hochvernetztem Produkt-Produktions-CoDesign. Zeitschrift für wirtschaftlichen Fabrikbetrieb, 118(12), 820-825. |